Mobile:+86-17717520739

Wechat:17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

Model:

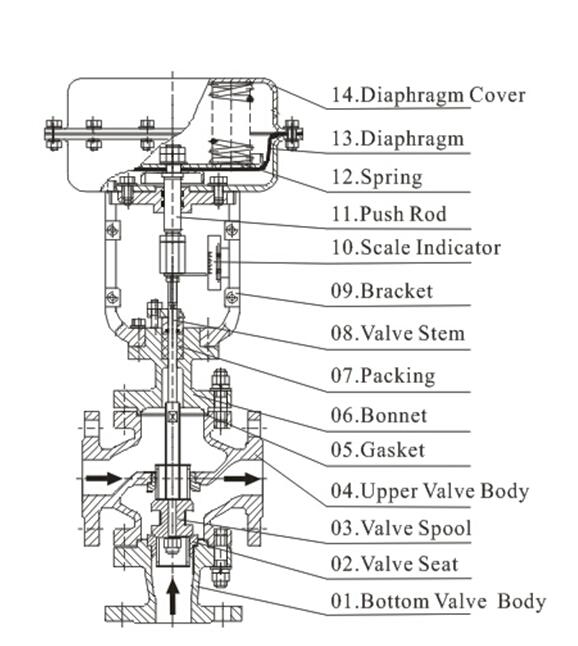

| Pneumatic mixing three way control valve Body type: | three way casting globe type |

| Spool type: | three way double seat spool |

| Nominal size: | DN20~300 NPS 3/4〞~ 12〞 |

| Nominal pressure: | PN16 ~ 100、 CLASS 150LB ~ 600LB |

| Connection: flange: | FF、RF、MF、RTJ |

| Welding: | SW、BW |

| Flange dimension: | According to to IEC 60534 |

| Pneumatic mixing three way control valve Bonnet type: |

Ⅰ:standard type(-20℃~230℃) Ⅱ:Radiator type: (-45℃~ high than 230℃ occasion) Ⅲ:Low temperature extended type(-196℃~ -45℃) Ⅳ:Bellow seal type Ⅴ:Warm insulation Jacket type |

| Packing: | V type PFTE packing, flex. graphite packing, etc. |

| Gasket: | Metal graphite packing |

| Control valve Actuator: | Pneumatic:multi-spring diaphragm actuator, piston type actuator. |

| Component name | Control Valve Material |

| Body/Bonnet | WCB/WCC/WC6/CF8/CF8M/CF3M |

| Valve spool/Seat | 304/316/316L(overlaying stellite alloy) |

| Packing | Normal:-196~150℃ is PTFE,RTFE,>230℃ is flexible graphite |

| Bellow | 304,316,316L |

| Gasket | Normal:Stainless steel with flexible graphite,Special:Metal tooth type gasket |

| Stem | 2Cr13/17-4PH/304/316/316L |

| Diaphragm Cover | Normal:Q235,Special:304 |

| Diaphragm | NBR with reinforced polyester fabric |

| Spring | Normal:60Si2Mn,Special:50CrVa |

| Pneumatic three way control valve Flow characteristic | Linear, percentage | |

| Allowable range | 30: 1 | |

| Rated Cv value | Percentage / linear CV8.5~1280 | |

| Pneumatic three way control valve Allowable leakage |

Metal seal: IV grade(0.01% rated capacity) Leakage standard: GB/T 4213 |

|

| Pneumatic three way control valve Performance | ||

| Intrinsic error(%) | ±1.5 | |

| Return difference(%) | ≤1.5 | |

| Dead zone(%) | ≤0.6 | |

| Difference from beginning to end point(%) | ±2.5 | |

| Rated travel difference(%) | ≤2.5 | |

| Special test | Material penetration flaw detection (PT), radiator test (RT), flow characteristic test, low temperature test. |

| Special treatment | Trim nitrogen treatment, seat hard alloy treatment. |

| Special rinse | Degreasing and dehydration treatment |

| Special condition | Special piping or connection, vacuum condition, S.S fastener, special coating. |

| Special dimension | Customized face to face length or dimension |

| Test and inspection | Third party test report |

| Pneumatic mixing three way control valve Type\ Method |

Pneumatic diaphragm actuator |

| ZH23~ZH56 | |

| Multi-spring type | |

| Usage | Regulating type, ON-OFF type |

| Air supply pressure or Power supply voltage | Air supply pressure (Spring range) 140(20~100)Kpa G 240 (40~200) Kpa G 280 (80~240) Kpa G |

| Connector | Air pipe connector: RC1/4 |

| Direct action | Pressure increase, stem descend, valve close. |

| Reaction | Pressure increase, stem ascend, valve open. |

| Input signal | 40~20mA.DC(with positioner) |

| Lag | ≤1%FS(with positioner) |

| Linear type | 2%FS(with positioner) |

| Environmental temperature | -10℃~+70℃ |

| Pneumatic mixing three way control valve Accessories |

E/P, P/P valve positioner, filter regulator, valve converter, solenoid valve, limited switch Non-standard accessories, need special customized notes. |

| Seat diameter(mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||

| Rated flow coefficient, CV | 8.5 | 13 | 21 | 34 | 53 | 85 | 135 | 210 | 340 | 535 | 800 | 1280 | ||

| Nominal size | Travel | Option flow coefficient Cv(★standard ●recommended) | ||||||||||||

| DN25 | 16 mm | ★ | ||||||||||||

| DN32 | 25 mm | ★ | ||||||||||||

| DN40 | ● | ★ | ||||||||||||

| DN50 | ● | ● | ★ | |||||||||||

| DN65 | 40mm | ★ | ||||||||||||

| DN80 | ● | ★ | ||||||||||||

| DN100 | ● | ● | ★ | |||||||||||

| DN125 | 60mm | ★ | ||||||||||||

| DN150 | ● | ★ | ||||||||||||

| DN200 | ● | ● | ★ | |||||||||||

| DN250 | 100mm | ● | ● | ★ | ||||||||||

| DN300 | ● | ● | ★ | |||||||||||

| Pneumatic actuator Diaphragm area, Ae (cm2) |

ZHA/B-23 | ZHA/B-34 | ZHA/B-45 | ZHA/B-56 | ||||||||||

| 350 | 560 | 900 | 1600 | |||||||||||

| Action | Spring range | Pneumatic mixing three way control valve Metal sealing allowable pressure difference(MPa) |

||||||||||||

| Air open | 20-100KPa | 0.7 | 0.44 | 0.28 | 0.18 | 0.17 | 0.11 | 0.07 | 0.07 | 0.05 | 0.03 | 0.05 | 0.03 | |

| 40-200 KPa | 2.14 | 1.31 | 0.84 | 0.53 | 0.51 | 0.33 | 0.21 | 0.22 | 0.15 | 0.09 | 0.11 | 0.07 | ||

| 80-240 KPa | 4.99 | 3.05 | 1.95 | 1.25 | 1.18 | 0.78 | 0.5 | 0.51 | 0.36 | 0.21 | 0.21 | 0.15 | ||

| Air close | 20-100KPa | 2.14 | 0.87 | 0.56 | 0.35 | 0.34 | 0.22 | 0.14 | 0.15 | 0.1 | 0.06 | 0.05 | 0.03 | |

| 40-200 KPa | 6.4 | 5.86 | 3.64 | 2.3 | 2.21 | 1.43 | 0.91 | 0.95 | 0.66 | 0.37 | 0.11 | 0.07 | ||

| 80-240 KPa | 6.4 | 6.4 | 5.04 | 3.18 | 3.06 | 1.98 | 1.26 | 1.32 | 0.92 | 0.52 | 0.21 | 0.15 |

||